1. Application of frequency converter in long car

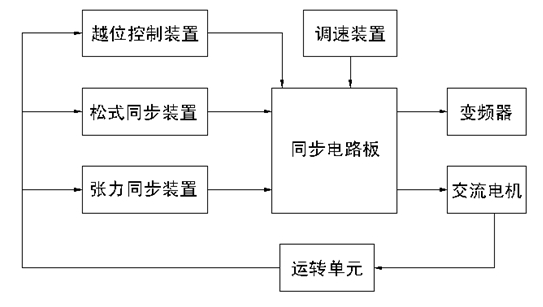

Most of the printing and dyeing equipment are long cars ranging from tens of meters to more than 100 meters. Multiple motors drive each roll, guide belt, drying cylinder and various swing frames to rotate at the same time. The layout speed of each unit must be consistent, and the absolute error must be automatically corrected soon. The customer changes the DC motor of each unit to the AC motor controlled by qd800 series frequency converter, equipped with self-developed synchronization plate, tension synchronization device, loose synchronization device, non-contact offside protection device and guide belt deviation correction device, its synchronization and reliability can be greatly improved, the lifting speed is stable, the fault is greatly reduced, and the product quality is improved, Rarely stop and find defective products due to electrical failure. So far, our enterprise has installed and used more than 80 qd800 frequency converters on long cars such as circular screen printing machine, re bleaching machine, mercerizing machine, setting machine, soaping machine, desizing, scouring and bleaching combined machine and high-temperature tenter, and is ready to change all other long cars to frequency conversion control in about a year. The control diagram of long car frequency conversion system is shown in Figure 1:

Fig. 1 control diagram of long vehicle frequency conversion system

2. Application in air conditioning, water pump, air compressor, circulating oil pump and other equipment with large load and load change

The motor power of these equipment is large, and they generally do not stop at the production stage (shutdown and maintenance once a month), but the load required in each production period changes greatly. For example, the load in late night is very small, sometimes even zero. At this time, the equipment still operates at constant power, and the power consumption remains unchanged. If qd800 series frequency converter is used to control the speed change of AC motor and keep the required water pressure, steam pressure, oil pressure, oil temperature and room temperature unchanged, the motor will run at a reduced speed when the load is small, which can greatly save electric energy.

3. Application of precise displacement control

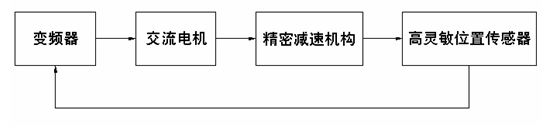

The edge detector, edge absorber and guide belt deviation correction device on printing and dyeing equipment need to accurately control the position of cloth edge and guide belt edge, otherwise the product quality can not be guaranteed. In the past, mechanical contacts, Hall elements, photoelectric switches and other detection devices were used to control the motor or solenoid valve to adjust the displacement of cloth edge and conduction band edge. Although it can receive certain results, it can not meet the ideal accuracy requirements. After that, the photosensitive potentiometer or combined photoelectric switch is used as the detection element, and the superior control performance of the frequency converter is used to make the AC motor start and stop quickly, so as to accurately control the position of the cloth edge, and the effect is better to control the position of the guide edge of the circular screen printing machine with the guide belt deviation correction device developed by us. The system control diagram is shown in Figure 2:

Fig. 2 system control diagram

4. Replace the complex and bulky mechanical speed regulation mechanism with frequency conversion speed regulation

For example, a large AC motor drives the main roller, along needle roller and reverse needle roller to rotate in the steel wire roughing machine. The speed of the along needle roller and reverse needle roller is adjusted through the heavy mechanical gearbox to achieve good roughing effect. The speed regulation is only based on the operator's feeling. We use qd800 frequency converter to replace mechanical speed regulation, the adjustment accuracy is greatly improved, and there are digital display instructions, and the use effect is very ideal.

5. Application of large motor soft start

Now we use frequency converter to control soft start of induced draft fan and blower of oil boiler.

6. Other applications

We have replaced the original DC speed regulation with frequency conversion speed regulation on the scraping unit, baking machine, singeing machine, drum machine and calender of flat screen printing machine. The equipment runs smoothly and the failure rate is reduced, and satisfactory results have been achieved.