The next process of each sizing machine often carries nearly 100 shuttleless looms. Its operation status and sizing quality directly affect the whole industrial chain. This paper introduces the application of qd800 column frequency converter in sizing machine in detail.

1、 Introduction

Qd800 series frequency converter is a high-performance closed-loop vector frequency converter, which can be used to control asynchronous AC induction motor and permanent magnet synchronous motor. The product adopts speed sensorless vector control technology completely synchronized with the current international leading technology, uses DSP control system, and strengthens product reliability, environmental adaptability and customized and industrial design, with more optimized functions, more flexible applications and more stable performance. Qd800 series frequency converter, as its derivative series, is specially used for the control of constant tension winding.

2、 Control requirements

This paper only takes the requirements of qd800 series frequency converter in the transformation and use site of sizing machine in a cotton mill as an example. The specific control requirements are as follows:

The main drive of the whole system is driven by two frequency converters, of which the winding frequency converter is 22KW and the traction frequency converter is 18.5kw. The requirements for frequency converter and control mainly include:

a) All are closed-loop vector control, in which the winding frequency converter can also calculate the winding diameter through the winding macro, and has the function of open-loop tension torque control.

b) Two frequency converters are master-slave control speed synchronization.

c) Excellent communication performance and good anti-interference performance of frequency converter communication.

d) Support common DC bus connection.

3、 Introduction to qd800 series frequency converter

Qd800 series special frequency converter for tension control is positioned as a special frequency converter for supporting and transformation markets such as textile industry. It has the functions of tension control and coil diameter calculation control, and meets the needs of medium and high-end winding applications.

In the functional algorithm, there is a special module for tension control to realize the function of special tension control frequency converter for central winding, unwinding and other process occasions, such as a complete set of solutions for unwinding, intermediate section, winding and other process sections.

Using qd800 series special frequency converter for tension control can not only completely replace torque motor, DC motor and tension controller to form a tension control system independently, but also make the system more concise, reduce cost, easy to maintain and obtain more stable control effect compared with the traditional tension controller plus frequency converter control scheme.

4、 System wiring and commissioning

4.1 wiring diagram of frequency converter system

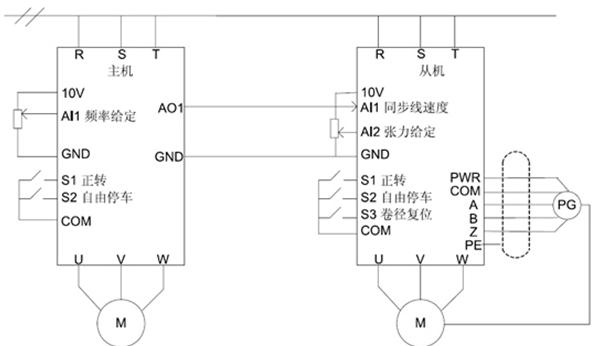

System wiring diagram 1

1. The master and slave operate in closed-loop vector mode, in which the slave also performs open-loop tension torque control with winding diameter calculation by the winding macro of the frequency converter.

2. PLC sends operation signal, stop signal and frequency setting to the host in real time, and sends operation signal, stop signal, coil diameter reset signal and tension setting to the slave.

3. In order to prevent misoperation, the winding diameter reset function is only effective in the shutdown state.

4. The master sends the synchronization speed signal to the slave in real time to realize the master-slave control of speed synchronization.

4.2 frequency converter parameter setting

Taking winding frequency converter as an example, some key parameters are shown in Table 1 for open-loop tension torque control in closed-loop vector mode. The parameters of traction frequency converter are simpler than those of winding frequency converter, which is in closed-loop vector mode.

Winding frequency converter:

Function code | Set value | remarks |

P0-01 | 1 | Closed loop vector control |

P0-02 | 1 | Terminal control |

P0-10 | 100 | Maximum output frequency |

P0-12 | 100 | Upper limit of operating frequency |

P2-09 | 1 | Set the upper limit frequency of forward rotation control torque through Ai1 |

P2-10 | 100 | Torque control forward rotation upper limit frequency keyboard setting |

P1 group | Refer to motor nameplate | |

P4-00 | 1 | Forward rotation |

P4-01 | 8 | Free parking |

P4-02 | 25 | Coil diameter reset |

Table 1: winding frequency converter parameters

5、 Conclusion

Our qd800 Series High-Performance closed-loop vector frequency converter and its derivative qd800 series special frequency converter for tension control have been successfully applied in two unit and seven unit sizing machines in many sites, which provides a performance basis for our products and solutions in this industry. However, from the perspective of electrical control system, the development trend of sizing machine in recent years is more and more towards segmented synchronous motion control and bus technology. The requirements for the driver are higher and higher, which is no longer satisfied with the traditional frequency converter scheme, and the requirements for the full servo motion control scheme are becoming more and more obvious.

As an important model for post spinning finishing and pre weaving preparation, sizing machine plays an irreplaceable role and should be the key model in our promotion in the whole textile machinery industry. The successful application in sizing machine will also drive the application of our products in winding machine, warping machine and other related models.