1、 Overview

Digital control machine tool, referred to as NC (numerical control) for short, is a mechatronics product integrating mechanical, electrical, hydraulic, pneumatic, microelectronics and information technologies. In the production of modern machine tools, it is generally driven by multiple motors, and the spindle and each feed system are driven by their own motors. Due to the wide processing range of the machine tool, different workpieces, different processes and different tools are used, the executive parts of the machine tool are required to have different motion speeds. Therefore, the main motion of the machine tool should be able to carry out stepless speed regulation. The spindle speed regulation system generally adopts AC spindle system.

With the development of variable frequency speed regulation technology, the AC drive of the spindle of NC machine tool can also meet the needs. The main drive motor drives the main shaft to rotate through belt drive, or drives the main shaft to rotate through belt drive and reduction gear in the main shaft box (to obtain greater torque). Due to the wide speed regulation range of spindle motor and stepless speed regulation, the structure of main axle box is greatly simplified.

2、 Working principle

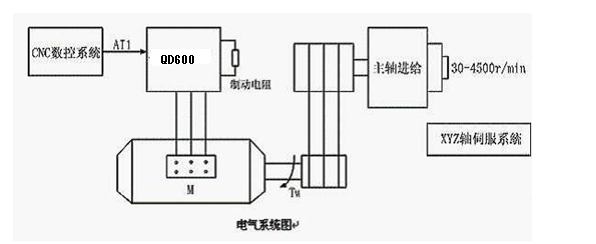

1. The composition of CNC system is shown in the figure below:

Frequency converter: qd600-37r5gb

Braking resistance: 80 Ω / 750W 7.5kW speed regulating motor

3、 System configuration

1 requirements for motor

It is usually required to use variable frequency motor or ordinary motor with fan to meet the heat dissipation requirements of motor at low frequency, and the speed regulation range of motor is required to be wide.

2 technical requirements for frequency converter

A large low-frequency torque is required

150% rated torque can be obtained at low frequency (1 ~ 10Hz).

B fast torque dynamic response and high speed stabilization accuracy

It can achieve good dynamic response effect. According to the change of load, it can respond quickly through the change of output torque, so as to realize the stability of shaft speed.

C. slow down and stop quickly

Generally, the acceleration and deceleration time of NC machine tools is relatively short. The acceleration time depends on the performance of frequency converter, and the deceleration time depends on external braking resistance or braking unit.

D) high reliability

The frequency converter has low failure rate and stable and reliable operation

E electromagnetic compatibility

CNC machine tool is an industrial application environment, which not only requires the frequency converter to have strong anti-interference ability, but also can not interfere with the peripheral control equipment.

According to the working principle of the frequency converter, the output of the frequency converter contains certain harmonic components. If it is not handled properly in use, it will interfere with other equipment. The most easily disturbed equipment on the NC machine tool is the CNC controller. Once the CNC controller is disturbed, the system will not work normally. In particular, the frequency command and operation command of the frequency converter may also be disturbed. If the interference is serious, it will cause instability of the frequency command, misoperation of the frequency converter, etc. The way to solve such problems is to pass strict EMC test when the frequency converter leaves the factory, and adopt frequency converter products that pass EMC test.

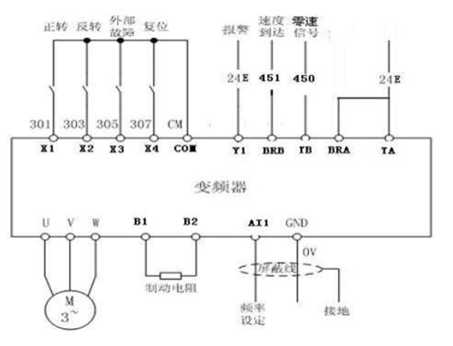

3. Wiring schematic diagram of frequency converter

4、 Parameter debugging

P0.01 = 2 terminal Ai1 is analog input

P0.04 = 1 external terminal control

P0.07 = 150 (maximum output frequency)

P3.03 = 14 (external fault shutdown)

P3.17 = 2 (speed arrival)

P3.14 = 19 (fault output)

P2.06 = 6 (carrier frequency)

P9.00 = 100 (slip frequency compensation gain)

P3.01 = 1 (x1 forward rotation)

P3.02 = 2 (x2 reverse)

P3.04 = 6 (x4 reset)

5、 System advantages

Odroer qd600 series frequency converter has the advantages of low rate, large output torque, high speed accuracy, reasonable price, complete functions, stable and reliable quality. It is an ideal choice for machine tool equipment. Odroer qd600 series frequency converter has the following characteristics: 1. Special CPU for motor control, space vector PWM control, ultra silent and stable operation.

2. Good low-frequency torque characteristics, stable low-speed rated torque output.

3. Pass EMC test and have strong anti-interference ability.

4. Advanced automatic torque compensation function design, strong load adaptability.

5. Real time detection and control of output current, with good dynamic response ability.

6. Complete functions, up to 40 kinds of protection and alarm functions.