1、 Overview

With the development of economy, the demand for various profiles in all walks of life is increasing. As the main processing equipment in non-ferrous metal (zinc, aluminum, copper, etc.) industry, the number of profile extruders is also increasing. The existing profile extrusion machinery is the same as many hydraulic powered equipment. The motor and oil circuit are often designed according to the maximum capacity. In addition to the large pressure required in the die locking and extrusion process, the power frequency operation of the motor often wastes a lot of electric energy. In view of this situation, we have carried out energy-saving transformation of aluminum profile extruder for the purpose of energy saving. The energy-saving control device of aluminum profile extruder independently developed and produced by our company has been verified at the customer's site, and the energy-saving effect is remarkable.

2、 Energy saving analysis and advantages of using energy-saving control system:

1. Energy saving in working process:

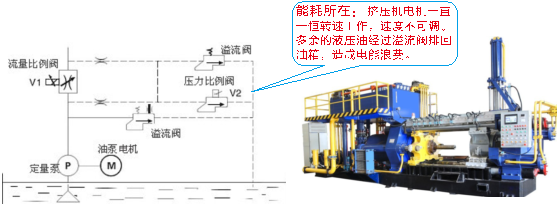

The working process of the energy-saving extruder of aluminum profile extruder is generally divided into several stages, such as feeding, jacking, extrusion, back off, cutting off, etc. the flow and pressure required in each stage are different. Among them, the extrusion time is longer (90%) and the energy consumption is more (90%). Its speed and pressure are regulated by the flow proportional valve and pressure proportional valve, The flow and pressure are controlled by adjusting the opening of the flow proportional valve and the pressure proportional valve. For oil pump motor, it is in full speed working state for a long time; The extrusion process is in a changing load state. In the hydraulic system of the extruder, the oil pump provides a changing flow, but the motor speed remains constant, and there is still excess hydraulic oil flowing back to the oil tank through the overflow valve. This process is called high-pressure throttling. The energy loss is as high as 15% ~ 35%. Because the oil supply of the oil pump is directly proportional to the speed of the motor, we can eliminate the overflow phenomenon by adjusting the oil supply of the oil pump to be consistent with the actual flow demand of the extruder, so as to achieve the purpose of energy saving.

2. Small starting current, no impact, prolonging the service life of the equipment and reducing maintenance costs:

Although the existing extrusion equipment uses step-down startup, the current impact is still large during startup, resulting in power grid fluctuation and great impact on the equipment, and the service life of motor, oil pump and other equipment is greatly reduced. Through the motor soft start function of energy-saving control system, the motor can be started gently with small current, which reduces the impact, reduces the maintenance cost and improves the service life of the equipment.

3. Perfect protection function:

It has good overload, overvoltage, overcurrent, short circuit and fault protection functions.

3、 Site modification scheme:

1. Transformation principle:

Under the condition that the original service conditions and operating habits remain unchanged, the original "star triangle" power frequency mode is converted to an energy-saving operation mode with variable speed according to the different processes of the extruder. The original mode and energy-saving mode can be switched at any time.

The original motor runs at full speed and the flow is controlled by the plunger pump, but the energy-saving controller controls the motor speed in real time to realize the energy-saving operation mode of flow control. In the whole process, the pressure and flow required by each process of the extruder are fully met, and the wasted power of the original no-load motor is saved.

2. Site photos of installed operation:

4、 Energy saving data accounting of extruder (two 55kW or two 65kW motors for each extruder in the market)

(1) Energy saving data accounting:

Serial number | Unit price of electricity | Motor power | Number of motors | Load rate | Operation days | Daily running time |

1 | 0.80元 | 65KW | 2 sets | 65% | 300 days | 24 hours |

1. Calculated according to the power saving rate of 12%:

2. Power consumption at rated speed: 65kW × 2 sets × 65% × 300 days × 24h = 608400 degrees;

3. Power saving under energy-saving control operation: 608400 degrees × 12% = 73008 degrees;

4. Electricity saving under energy-saving control operation: 73008 kWh × 0.8 yuan / degree = 58406 yuan;

(2) Energy saving data accounting:

Serial number | Unit price of electricity | Motor power | Number of motors | Load rate | Operation days | Daily running time |

1 | 0.80 yuan | 55KW | 2台 | 65% | 300 days | 24 hours |

1. Calculated according to the power saving rate of 12%:

2. Power consumption at rated speed: 55kW × 2 sets × 65% × 300 days × 24h = 514800 degrees;

3. Power saving under energy-saving control operation: 514800 degrees × 12% = 61776 degrees;

4. Electricity saving under energy-saving control operation: 61776 degrees × 0.8 yuan / degree = 49420 yuan;

5、 Quality assurance and after-sales service of this product:

1. Changle branch is established separately for the extruder market. The extruder market is resident in the company's sales personnel who are familiar with each enterprise and carry out business processing at any time.

2. The company takes "saving energy, reducing consumption and benefiting mankind" as its corporate mission and "service is only better, there is no best; satisfaction is only the starting point, there is no end." as its business philosophy, the company strictly controls product quality and ensures quality first.

3. Based on lean management, the company provides lean after-sales service to win the maximum economic benefits for customers.

Satisfactory service of aozhuo company

One goal: make customers 100% satisfied

Two first-class: provide first-class products and offer first-class services

Three Guarantees: ensure the provision of high-quality products, high-quality projects and high-quality services

6、 Ozhor product service terms

1) . the warranty period is one year from the date of delivery. If there is any quality problem, the product shall be repaired free of charge during the warranty period (except for improper use of the machine, force majeure factors, human factors, etc.). Beyond the warranty period, aozhuo engineers will still provide relevant services in a warm and thoughtful manner.

2) Product service time - the telephone of the aozhuo service center is opened 24 hours. After receiving the customer's telephone, the aozhuo engineer will come up with a solution to the problem or send relevant personnel to the site within 2 hours in principle.